"MM54" (mm54mk2)

"MM54" (mm54mk2)

04/25/2016 at 22:06 ē Filed to: Sim_Build

1

1

9

9

"MM54" (mm54mk2)

"MM54" (mm54mk2)

04/25/2016 at 22:06 ē Filed to: Sim_Build |  1 1

|  9 9 |

With the work recently beginning on the Chevelle project, one may think Iíve forgotten my other project (which was supposed to be my fall project, so that the end result would entertain me through the winter... about that...). This isnít the case, Iíve just been busy and waiting to get the chance to grab and cut down more wood. Picking up where the last post !!!error: Indecipherable SUB-paragraph formatting!!! ...

The custom seat rails needed secured to the platform - simple enough, I just removed them from the seat, marked up the platform, and screwed them down from the other side of the board.

Those arenít metal inserts, the washers just stuck in the wood when I took the bolts out.

Then itís just a matter of re-bolting the seat on the aluminum rails onto the wood, and hey, itís a seat!

Next up is the pedals. As an advance word of warning to anyone with a set of pedal which come with a G27 - the center two threaded inserts are not only

off-center

from the housing, theyíre also not centered between the outer pairs of inserts, which actually

are

based around the center of the pedals. Spacing between them is, of course, metric. Bolts are M6.

Sawdust in the carpet!

Youíll want to drill the holes big enough that you have some wiggle room; itís hard to get 6 holes lined up. You can always put bigger washers under the heads of the bolts underneath.

Reminder: at some point Iíll be taking this apart to paint all the wooden parts and carpet the base with automotive carpet

Comfort of seat position vs. pedals is now verified. The seat does slide +/- 3 inches from where it sits as shown above, so thereís adaptability for people with different legs than I have, too!

But somethingís missing..

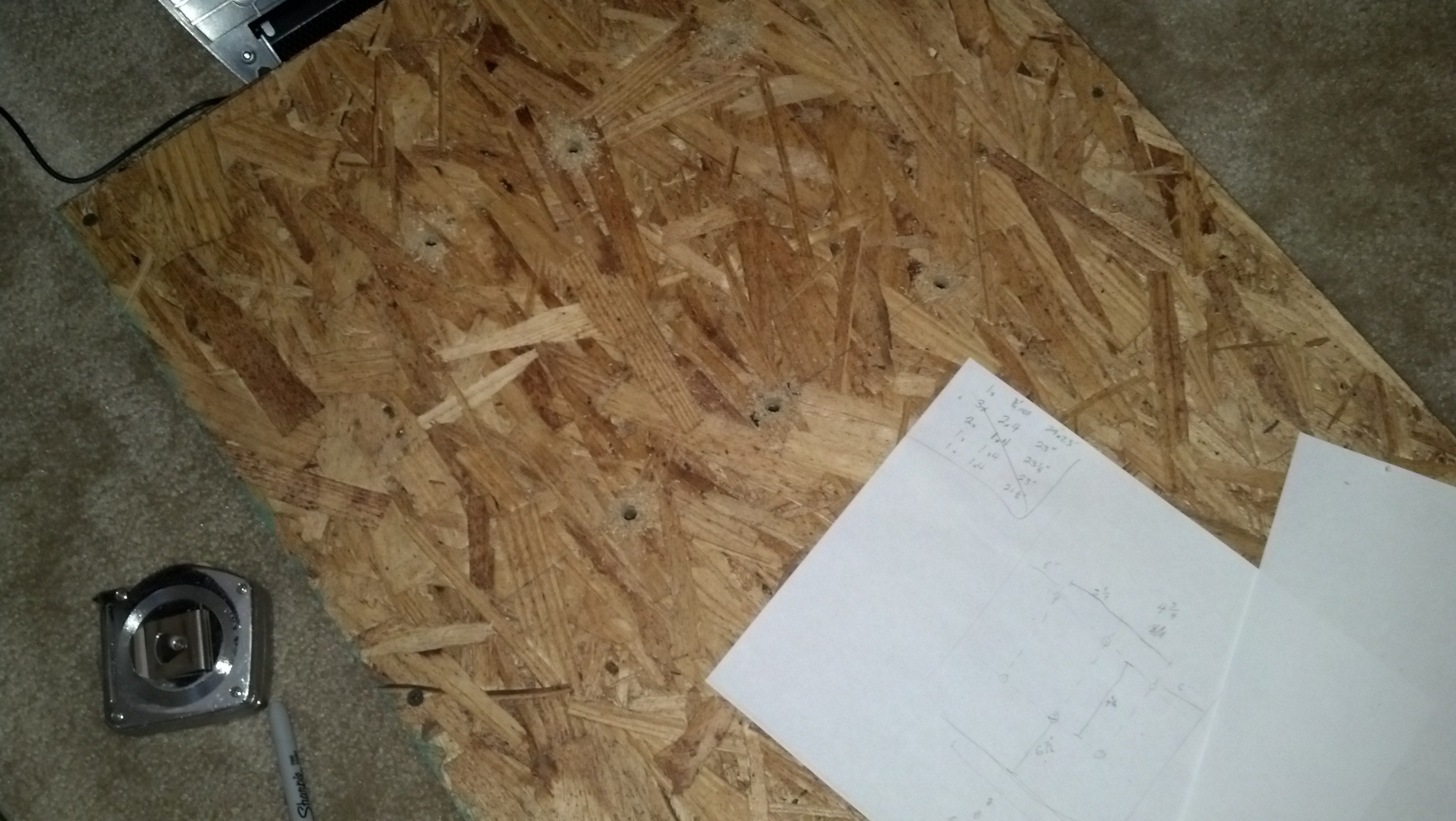

Next up was to lay out the materials Iíve been quarter-assedly working on coming up with for the past two months and realize I botched one of the measurements (at least it wasnít an important one). Everything was laid out, and the plywood pre-drilled to simplify assembly.

So much sawdust in the carpet

Next comes putting it together. Because wood is never actually straight/flat/square, and this needs to be straight/flat/square and not-wobbly, clamps come in very handy to coerce the wood into place.

Itís like a giant spring. If all the screws suddenly disappear, itíd practically come apart like a bomb.

More clamps, more screws, more clamps, more screws, more clamps, more screws. Much like masking (well) for paint, clamping wood together to make it square and stay that way is as much a black magic art as it is science.

I actually do have lights in my apartment, my phone just thinks itís perpetually night.

More clamps, more screws, clamp, screw, clamp, screw, clamp, screw...

Fifty shades of CLAMPS

Clamp, screw, clamp, screw... hey look a three-legged table!

In hindsight, I pretty much re-invented the wheel and built 75% of a workbench with impractically short legs.

The legs are temporarily only held with two screws each in case I have to take them off to shorten them, or replace them with taller ones. Once the height is verified, the legs will get several more screws in key locations to stiffen the table.

Now, mock it up.

Oooh

No, really, mock it up

Finally feels like a racing seat!

Thatís better. As you can see, some of the clamps are still hanging around, this time holding the legs to the base and the side board, which needs to be shortened a few inches for ingress/egress, to the top.

Being 3/4" oak plywood (I was going to use MDF but this was laying around) the top is pretty stiff, and I believe that once itís secured well to the legs, and the legs to the base, it should be very stable. The final height of the wheel will be a little higher than shown here, since the legs wonít be sinking into the carpet. If it is still flexy, I can brace the underside a bit more.

Next up is to secure the legs to the top more securely, get more screws because I have 8 left, decide if I even need the brace clamped in place above, secure the legs to the base, and put a brace across the rear two legs for a little more side-to-side rigidity. After that, all thatís left is a shifter-holder (yet to be designed).

Any and all questions/comments are welcome, as always.

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> MM54

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> MM54

04/25/2016 at 22:15 |

|

Maybe make the wheel position adjustable?

It's a "Porch-uh"

> MM54

It's a "Porch-uh"

> MM54

04/25/2016 at 22:18 |

|

NO. IíM BUILDING A SIM RIG!

http://oppositelock.kinja.com/racing-sim-rigÖ

Stop copying me! :P

TheHondaBro

> It's a "Porch-uh"

TheHondaBro

> It's a "Porch-uh"

04/25/2016 at 22:34 |

|

HAY I WAS DOING IT FIRST!!

http://oppositelock.kinja.com/tag/project-siÖ

MM54

> It's a "Porch-uh"

MM54

> It's a "Porch-uh"

04/25/2016 at 22:43 |

|

Refer to my post (Part 0) from early January :)

Or HondaBruhís from way before then.

MM54

> BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

MM54

> BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

04/25/2016 at 22:45 |

|

Why? Iíve designed the whole thing around how it should go to fit me; adding adjustment just adds more chance for things to become loose (and adds complication/cost). The seat slides and reclines, and Iíve fine-tuned the height of the Ďtableí so itís good for me, and since I live alone, thatís all it needs to be good for.

tromoly

> MM54

tromoly

> MM54

04/25/2016 at 22:55 |

|

Have you sat in and ran your feet through the pedal travel yet? You may find about 10 degrees or so of angle is wonderful for that driving position.

Build looks good, makes me wish I wasnít away from home so much and could build a new rig.

DynamicWeight

> MM54

DynamicWeight

> MM54

04/26/2016 at 14:26 |

|

Iím the type of person who likes to fiddle. So height adjustable wheel would be nice, but I agree it probably adds a bit too much complication if the seat already slides.

MM54

> tromoly

MM54

> tromoly

04/26/2016 at 17:08 |

|

I have sat and played with the pedals, I may consider tilting them up a bit. Theyíre not bad, though

Xyl0c41n3

> MM54

Xyl0c41n3

> MM54

05/09/2016 at 21:18 |

|

Yo! We switched platforms. Drop me an email if youíd like an invite.

.

.

I.am.xyl0c41n3 @ gmail